Recycling paper is sustainable economy – but without new wood fibre from forests it would end quickly

A single wood fibre can be recycled even up to ten times. However, with the present recycling rate and process losses the fibre cycles only one to five times. To substitute for the loss, recycling needs new fibre, which can only be obtained by processing wood from forests.

It is important to use raw timber, virgin fibre, in board and paper products requiring better quality and characteristics. ”Should the use of timber be stopped, the manufacturing of board packages would very soon stop as well,” says Ulla Forsström, Principal Scientist at VTT Technical Research Centre of Finland Ltd.

The share of virgin fibre in board packages is close to 60 percent at the moment. If this share was removed, one could still manufacture board packages, but there are certain restrictions in the use of packages made only from recycled fibres.

Take, for example, packages for groceries – the use of recycled fibre is downright forbidden in them, due to product safety reasons. This is why stopping the use of virgin fibre would immediately lead to the use of alternative packaging materials, such as plastics.

What is more, the plastics must also be made of virgin material, that is, crude oil, because you are not allowed to use recycled plastics in packages for groceries. ”For example, you do not make new bottles out of recycled plastic soft drink bottles, but instead, you make textiles or park benches,” says Forsström.

If virgin fibre was not added, the quality of office and magazine paper, too, would weaken quickly. Due to this, the brightness and printing quality of the paper would weaken.

However, advertisers want to publish high-quality images in magazines. For the publishers, the situation would be more difficult than in the case of packages, because there is no immediate substitute for these paper grades.

Recycling is reasonable, but it weakens the fibre

According to Forsström, recycling as such is reasonable, because it is very resource-efficient. From the same raw material you can manufacture several products that can be sold one after the other. Forsström was the leader of the Reffibre research project financed by the European Union. Among other things, the project studied the recycling flows of European raw materials, such as wood fibres.

Manufacturing new products of recycled wood fibres uses very small amounts of different resources, such as energy, in comparison with the use of virgin fibres. The most energy-consuming phase in the use of raw timber is pulping, which means that the fibres are separated from each other in chemical or mechanical pulp production.

As regards recycled fibre pulp, you do not need to refine it any more, but for certain products, the pulp must be deinked and impurities and plastic coatings must be removed.

However, recycling and deinking weaken the fibre. The fibre loses the quality characteristics needed, such as strength, in each use. After a sufficient number of uses you can no longer recycle the fibre and it ends up in energy production.

To substitute for this loss, you need virgin fibre. If it is impossible to procure, the fibre mass in the recycling process first deteriorates and finally vanishes completely.

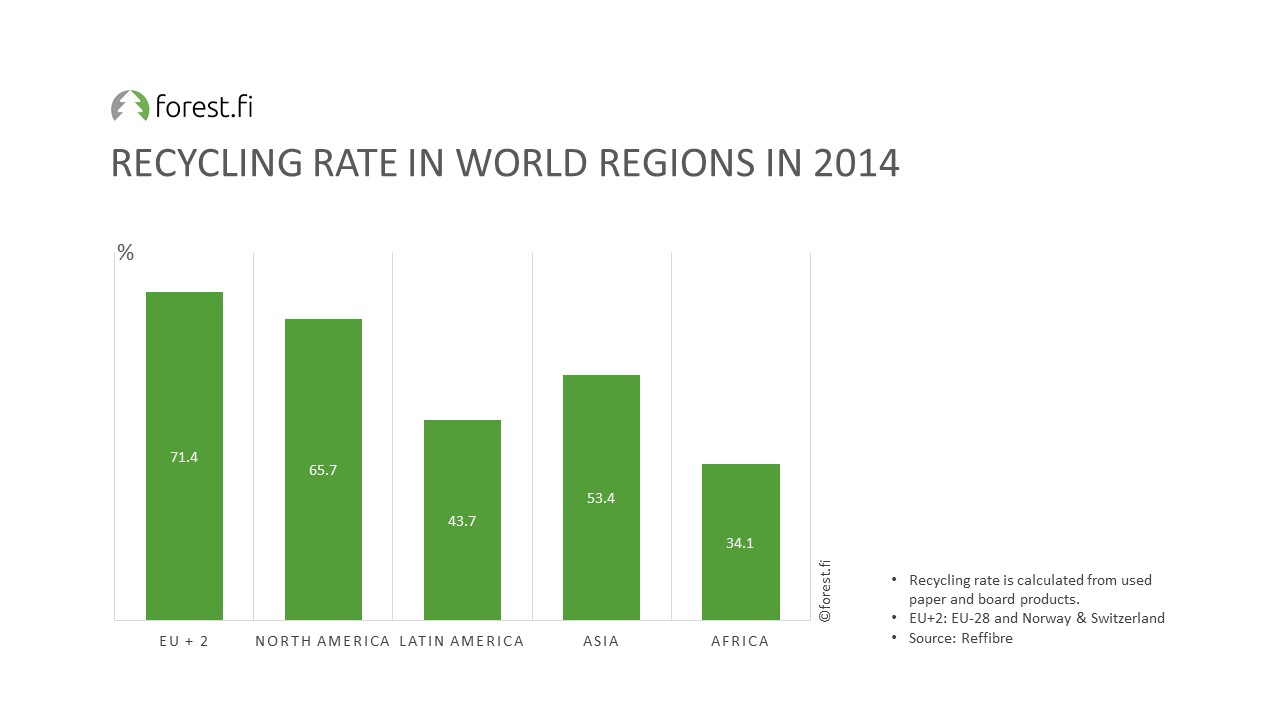

Europe is the most diligent paper recycler

For such products as office papers – or copypapers – and magazine papers, good printing qualities are essential. And they are difficult to achieve if there is too much recycled fibre in the paper.

On the other hand, packages are needed to transport items in internet shopping. They must withstand rough handling, sunshine and humidity, even rain. These properties, too, are difficult to reach, if the package contains too much fibre that has been recycled too many times.

Newsprint paper and other packages could be manufactured longer without virgin fibre. This is made easier because of the world’s most diligent recyclers: Europe recycles over 70 percent of the paper and board used.

But without virgin fibre the quality of these products would weaken as well. And within a relatively short time the weak fibres would vanish completely.

Some of the recycled fibre is removed from the cycles also because it is used in paper grades that cannot be recycled. For example, the fibres in tissue papers most often end up in energy production through wastewater treatment processes.

Recycled fibre is also used in technical papers, such as wallpaper and etiquette paper. However, paper is only one part of these products and separating it from the product is difficult, which makes the recycling too expensive to be profitable.

”The share of loss and removals from the process is so large in all recycling processes that even theoretically, one fibre cannot last more than five cycles on the average,” says Forsström.

Recycled fibre is an item of global trade

Global trade affects all the cycles as well. ”For example, the largest share of board packages manufactured in Northern America are made of virgin fibre, while the used packages are exported to China,” says Forsström.

Europe also exports recycled paper, mainly to Asia. The export consists mostly of groceries and outdoor packages, but office and magazine papers are exported as well.

According to Forsström, it is possible that China will ban the import of recycled paper, either totally or only as to some grades, as it has done for recycled plastics. This would cause significant effects on the global trade of all wood-based fibre.

”Already now, China imports almost all virgin fibre, that is chemical pulp, which they also look for in Finland,” says Forsström.

A large share of pulp manufactured in southern America is exported to China. ”And the same goes with Russia as well, where the pulp from the mills close to the Russian-Chinese border is exported directly to the Chinese market,” says Forsström.

An import ban of recycled fibre to China would decrease its demand and price everywhere in the rest of the world and would again increase the demand for chemical pulp, because it is only the virgin fibre material which China could substitute for the recycled fibre.

Webpage of Reffibre research project

Kirjoita kommentti