The beauty of cellulose: how talented students transform pulp into a super material

In Finnish universities, work to develop new applications of cellulose goes full speed ahead. Students combine their technology and design expertise to create sustainable everyday products.

The pale-coloured beer bottle has an elegant rough surface – and yet looks familiar. “We wanted to develop an approachable product. The shape intentionally resembles the traditional beer bottle, so that the new material would not feel too unappealing,” says Ms. Anneli Tyrväinen, who studies packaging and brand design at the Lahti University of Applied Sciences.

Created for the imaginary Mire Owl beer, the bottle is made of pulp with two percent peat added. According to Tyrväinen, peat adds texture to the product, but also some image value. The bottle is one of student projects carried out at the Hiilinielu [Carbon Sink] Design Studio. The studio is part of a multidisciplinary joint project of the Universities of Applied Sciences in Lahti and Tampere and of Design Forum Finland.

So far, the Mire Owl beer bottle is a prototype with too much weight. Mr. Olli Pilpola, Project Manager at the Hiilinielu Design Studio, believes that the new cardboard packaging products developed jointly by the design and engineering students will reach the store shelves.

“In the future you can perhaps package a loaf of oat bread in oats,” says Pilpola, showing a grade of cardboard containing 50 percent pine pulp and 50 percent non-edible parts of oats.

Networking leads to business

The idea behind the EU-funded Hiilinielu Design Studio is that Finland’s forests grow more timber than we know how to take advantage of. The project was presented at the Designing Cellulose for the Future II event in Helsinki in May. The aim of the exhibition and seminar was to strengthen collaboration between those working with wood cellulose.

Finland is known not only for traditional pulp and paper industry, but also for research into the new biomaterials. Designers and business professionals are needed as partners in materials research.

“Experts from different fields and experimental activity create a new kind of expertise that should be adopted widely,” said Ms. Anna Suurnäkki, Project Manager at VTT Technical Research Centre of Finland and one of the organizers of the Designing Cellulose event.

In the future, circular economy and the growth of sustainable consumption will increase the need for bio-based materials. “Finland can become the number one expert in wood-based biomaterials,” says Suurnäkki.

The Designing Cellulose event was organized by the research project Design Driven Value Chains in the World of Cellulose (DWoC), which is funded by the Finnish Funding Agency for Innovation Tekes. The DwoC believes cellulose to be a new super material: it is the most abundant renewable resource in the world and also recyclable and biodegradable. The project’s website, CelluloseFromFinland.fi, points out that the well-being and growth of Finnish forests have continuously improved in recent decades, thanks to good management and sustainable use.

Success in textiles

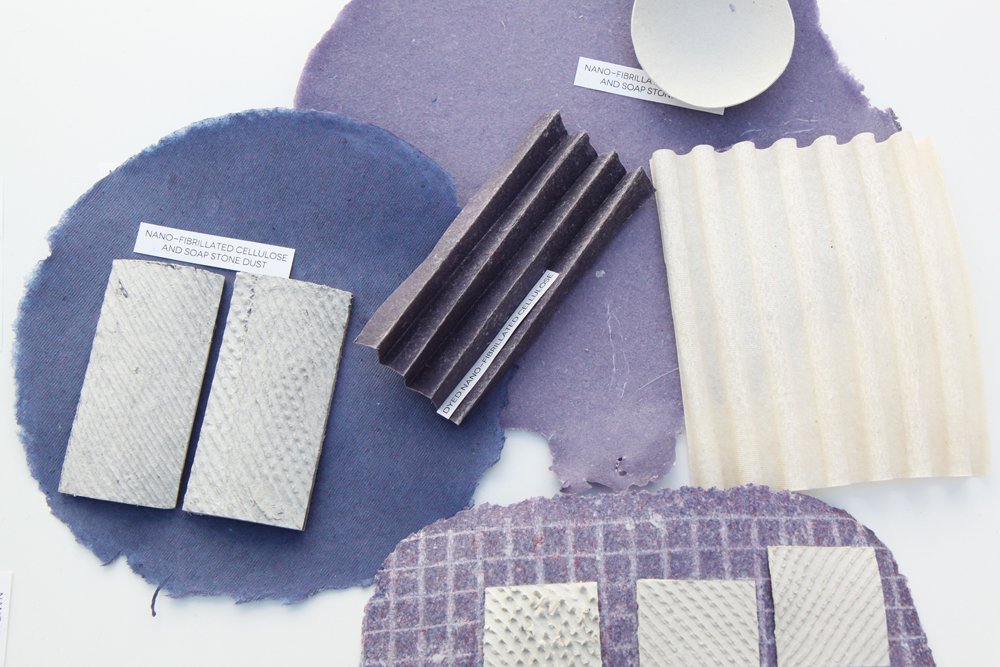

The Chemarts summer school of the Aalto University is one of the collaborations exploring cellulose. Students of the School of Chemical Technology (CHEM) and the School of Arts, Design and Architecture (ARTS) have developed, among other things, a new way to dye recycled fibres, edible bowls and plates, an antibacterial perspiration blocker and decomposable shoes.

Finnish materials research and multidisciplinary student co-operation have created promising technologies especially in the textile sector. The new way to wear wood is supported by the fact that growing cellulose fibres requires neither irrigation, as is the case with cotton, nor chemical-intensive processes, as with viscose.

One representative example of the new technologies is the Ioncell-F method, developed at the Aalto University together with the University of Helsinki and VTT. The method enables textiles to be produced in an environmentally friendly way, using birch cellulose and recycled cotton, for example. The famous Finnish textile label Marimekko has already piloted the technology, and it won the Global Change Award of the H&M Conscious Foundation, which sought ideas for sustainable development in the textile industry.

Another award winner is the R&D company Spinnova, which develops technology that turns wood fibres directly into yarns. A spin-off of the DWoC project by VTT, the company has been nominated as one of Finland’s most promising start-up companies.

CHEMARTS collaboration of Aalto University

Kirjoita kommentti